Preform

PS-21GP Series

PS-21GP Series 3 wheels rotary type whole surface inspection machine (Non-crystallized preform)

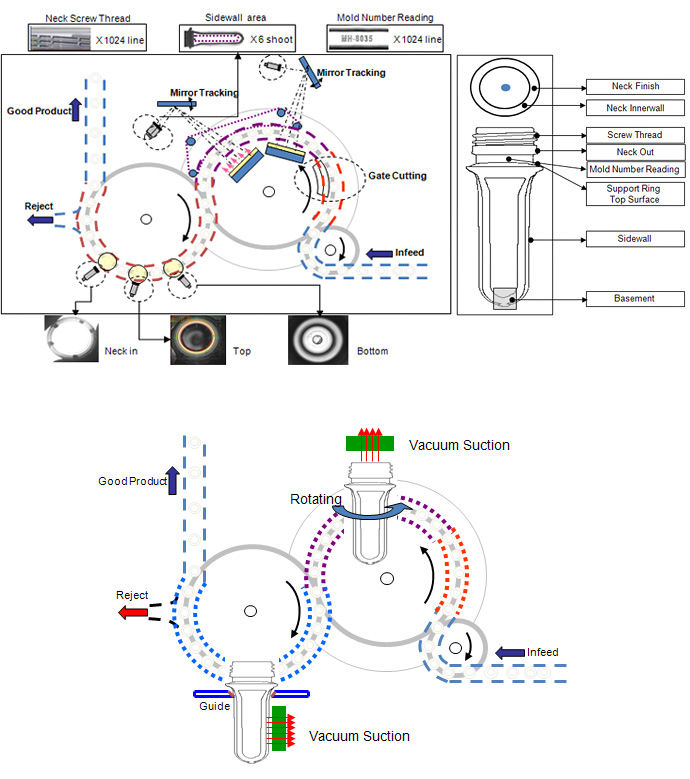

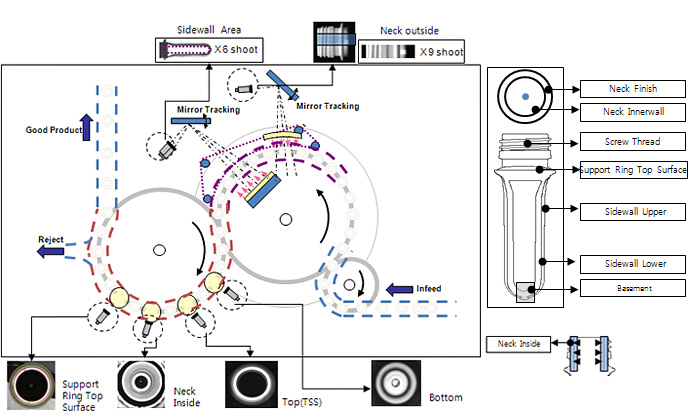

PS-21GP Seriesis a machine that ejects the all bad preforms by inspecting the entire surface of it, the inspected surface area includes Neck of preform, and this is possible with our specialized design structures like 3 wheels rotary type mechanical structure and Mirror tracking system.

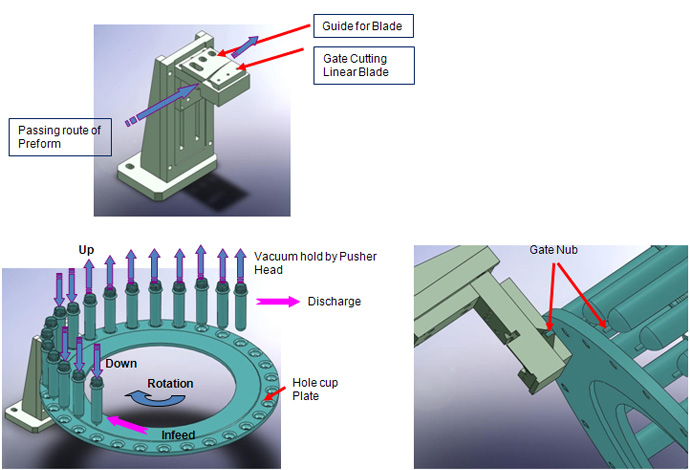

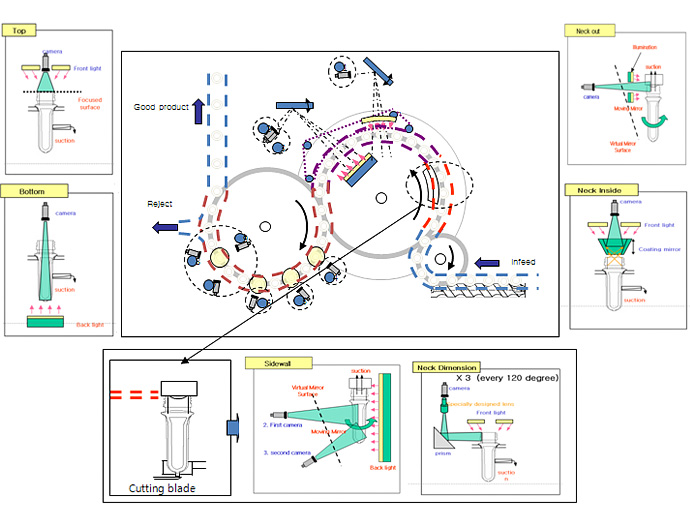

The Gate cutting process is required before the PET Blowing when the gate type is Long gate. At this moment, the customer will need Gate cutting equipment independently. However, because of the structure Gate cutting device is mounted integrally with the machine, you can consider the concept of a 2 in1 that customer does not need to buy an additional device. Moreover, the machine provides a reduction of investment cost and installation space. Additionally, the machine can reduce time according to the part changing.

Feature

- 3 Wheel Rotary Type structure

- Over 400 DegreePreform rotation in the body inspection area

- Mirror tracking system

- High-resolution Digital Camera

- Apply various patent technology

- Quick & Easy Change parts

- Install the safety device

- High-intensity LED illumination

- All-in-one Gate Cutter System

- All-in-one Gate Chip Collector

- Apply specialized inspection software

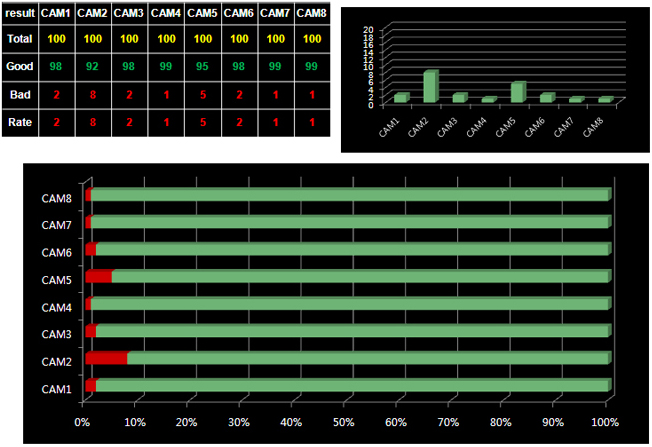

- Distinguished Data Static Program

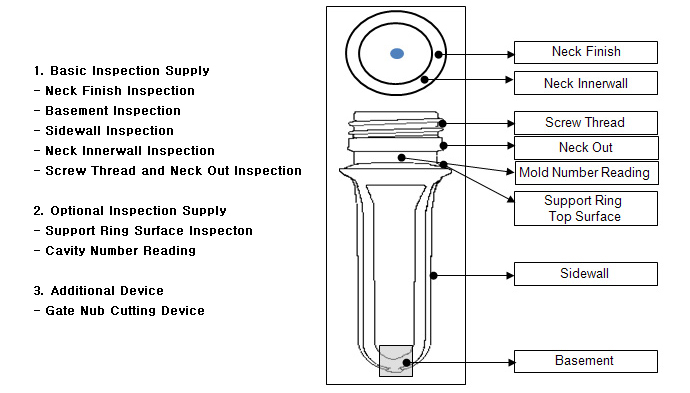

Inspection Item

- Neck Finish

- Bottom

- Body

- Neck Inner wall(Option)

- Screw Thread(Option)

- Support Ring(Option)

Standard Specification

| Size | 1,800 x 1,700 x 2,200 (H) |

| Weight | 2,700kg |

| Maximum Speed | 1000PPM (Non-Gate Cutter version) 500PPM(Gate Cutter version) |

| Electric Specification | 220/380/440V, 3Ph, 50/60Hz |

Non Crystallized PReform Inspection Area

Machine Configuration

Preform Gate Cutting Unit(Position of Blade)

PS-21RWP Series

PS-21RWP Series 3 wheels rotary type whole surface inspection machine (Crystallized preform)

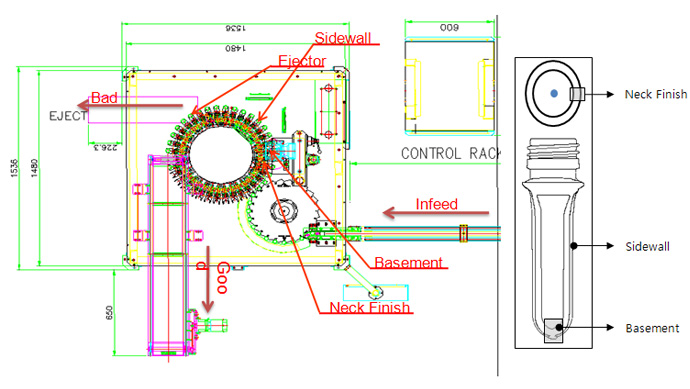

PS-21RWP Series is a machine that ejects the all bad preforms by inspecting the entire surface of it, the Inspected surface area includes Neck of preform, and this is possible with our specialized design structures like 3 wheels rotary type mechanical structure and Mirror tracking system.

For the Crystallized preform, certain inspections are required in order to inspect contamination, hydrocarbon, bubble, and etc. which might be occurred on the Crystallizing process. The PS-21RWP Series can inspect those bad factors which can be placed on deep position of neck inner wall precisely without blind spot within 17mm. This is possible by applying P&S designed special optical lens.

In addition, the wavy problem that can be occurred on the neck finish part while process of Crystallizing with high temperature in the oven. Our machine can beyond the limitation of previous machine vision system by adopting the high repeatable inspection method through the Air flow sensor and precision control function that installed independently.

Feature

- 3 Wheel Rotary Type structure

- Over 400 Degree Preform rotation in the body inspection area

- Mirror tracking system

- High-resolution Digital Camera

- Apply various patent technology

- Quick & Easy Change parts

- Install the safety device

- High-intensity LED illumination

- Apply specialized inspection software

- Distinguished Data Static Program

- Equipped independent Air flow sensor and controller(option)

Inspection Item

- Neck Finish

- Bottom

- Body

- Neck Innerwall

- Screw Thread

- Support Ring

- Wavy(option)

Standard Specification

| Size | 1,700 x 1,800 x 2,150mm (H) |

| Weight | 2,500kg |

| Maximum Speed | Low : 200PPM Middle : 400PPM High : 1000PPM |

| Electric Specification | 220/380/440V, 3Ph, 50/60Hz |

Machine Configuration

Preform Holding Process

PS-21PSI

PS-21PSI inspect the non-crystallization/crystallization preform with 2 wheel gripper structure as neck handling mechanism. The 2 wheel gripper structure is designed as an alternation of PS-21 GP series, it can inspect neck finish, bottom, and body only, but, the price of machine is less than other type, the customer who doesn’t want high specifications prefer to use this type.

The structure of Neck Gripper can be described as followed, during the conveying of preform in the inspection machine, the finger type gripper grasp the preform support ring and move. Even if the body size is different with same neck size, the machine doesn’t need additional change parts regardless the size of preform body.

Feature

- 2 Wheel Gripper handling structure

- High-resolution Digital Camera

- Quick & Easy Change parts

- Install the safety device

- High-intensity LED illumination

- Apply specialized inspection software

- Distinguished Data Static Program

- Possible to adjust height of discharging conveyor.

- Preform body inspection through 3 cameras

Inspection Item

- Neck Finish

- Bottom

- Body

Standard Specification

| Size | 1,600 x 1,500 x 2,100(H) |

| Weight | 1,900Kg |

| Maximum Speed | Low : 200PPM Middle : 400PPM High : 1000PPM |

| Electric Specification | 220/380/440V, 3Ph, 50/60Hz |

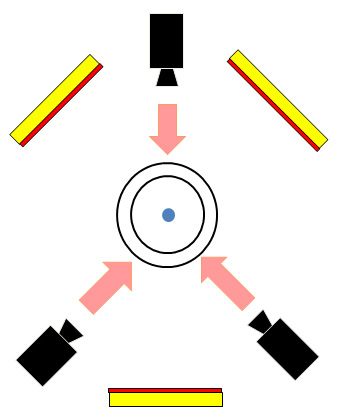

Machine Configuration

Sidewall Position Camera /3 camerawith 120 degree each

PS-PS-21TSS

PS-21TSS

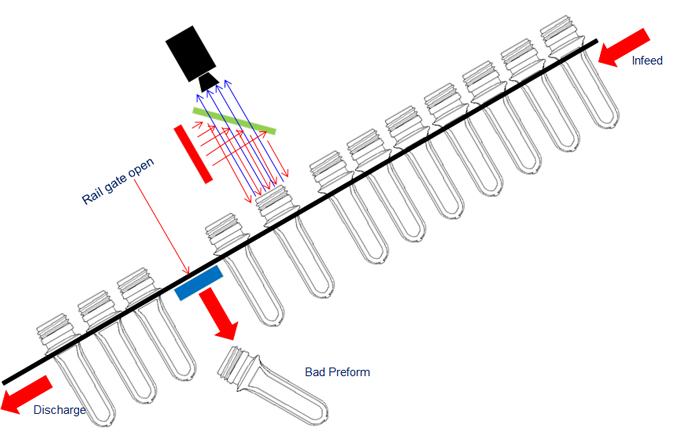

Top Sealing Surface inspection machine (Non-crystallized or Crystallized preform)

PS-21TSS is the machine with minimized mechanical structure for inspecting only Neck finish of preform.

This model is available and specialized for inspecting the foreign materials, contamination, ovality, and short shot through only one camera looking the neck finish of non-crystallized or crystallized preforms. The model has structure installed on the middle of sliding rail between oriental machine and Blower oven.

Feature

- 1 Wheel type structure

- High-resolution Digital Camera

- Quick & Easy Change parts

- Install the safety device

- High-intensity LED illumination

- Apply specialized inspection software

- Distinguished Data Static Program

Inspection Item

- Neck Finish

Standard Specification

| Size | 560 x 730 x 1,600(H) |

| Weight | 320kg |

| Maximum Speed | 1000PPM |

| Electric Specification | 220/380/440V, 3Ph, 50/60Hz |

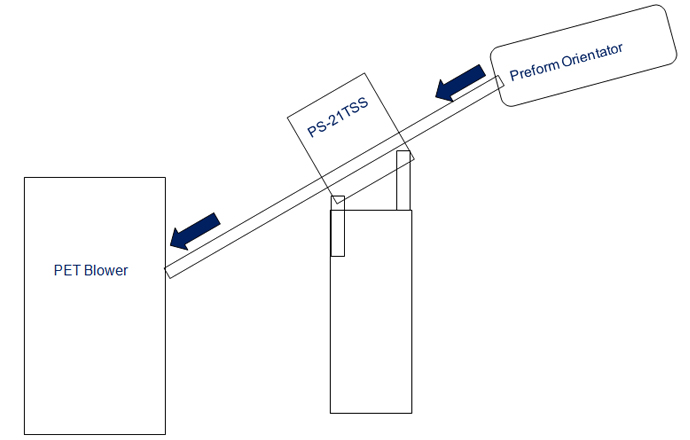

Installation Position

Camera and Eject Position

PS-21SP

PS-21 SP PET Preform Sampling Automatic inspection machine

PS-21SPis advanced system which can inspect the various defective cases from NG preform through Vision System during the production process, and the cases are building the Database based on Mold Number in order to providing the Statistic Process Control(SPC) for products.

This accumulated database is utilizing to generate the unusual alarm message to production manager or it can be printed out into Excel file or on paper for saving.

Regarding the inspection items, PS-21SP is designed for total solution system that inspects Foreign Materials, Contamination, Scratch, Notch, Ovality and Size Measurement that are all related about preform quality issues. For this, this model contains the all P&S abilities such as Special Camera, Special Lenses, Mirror System, and etc.

Feature

- Statistic process control(spc)

- Ui for real time data monitoring

- Building data based on mold no. Reading

- Select data by inspection date and time

- Sense quality issues & alarm by analyzing data

- Data managing( save in excel or print out

- Generate objective data through uniformed data

- Full automatic inspection

- Managing static data in detail mold no/ inspection area

InispectionItem

- Top Sealing Surface

- Bottom

- Mold No.

- Body

- Neck Out

Measurement Items

- Neck-in Size

- Neck-out Size

- Weight

- body transformation

Standard Specification

| Size | 2,000 x 1,500 x 1,800(H) |

| Weight | 750kg |

| Maximum Speed | 20PPM |

| Electric Specification | 220/380/440V, 3Ph, 50/60Hz |

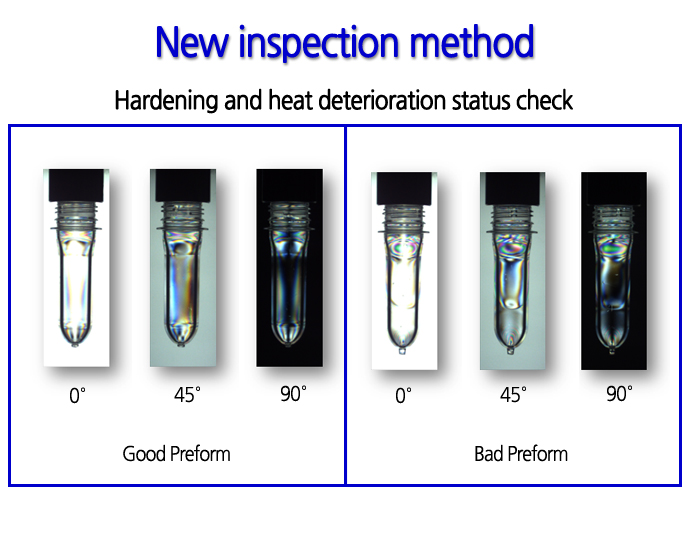

Inspection Method

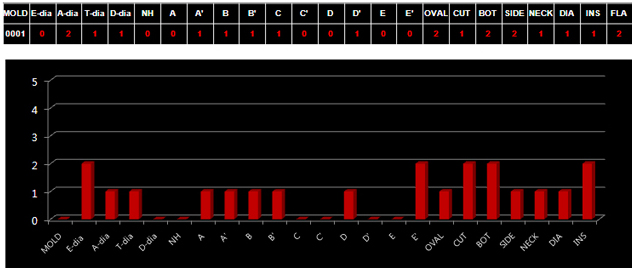

Total statistic Data of EaAch camera

Database of Bad preform