Hexaline

Description

Esit Hexaline Check Weigher measuries weights of each

products dynamically at high speed and defected products

while they are passing on the belt. Hexaline, which can

easily be adapted to the customer requests thanks to its

modular structure, has been designed in consideration of

the strict regulations in food and drug industry.

Status of the production line can be followed easily with

advanced graphic charts thanks to the easy-to-use software

and easily read touch screen of Hexaline.

The products which are out of the limit you’ve designated,

can be sorted from the production line into more than one

rejection scales with sound and visual alarm and reported

with Hexaline.

With Hexaline, your production lines will run in compliance

to the latest legal sanction and directives adopted in your

industry.

It is possible to use it for sorting the products according to

there weights.

Specifications

- Easily read 10.4” colour touchscreen control panel.

- Selectable weight type and unit: Net, Gross, Quantity, g, kg,lt, ml, N, lb, oz

- Counting pieces inside the package

- Remote access and taking report

- Reporting on shift, day, month and year basis.

- Smart automatic reset

- Fully open design easily accessible for service

- Completely stainless bearing trays

- Structure than can be removed and adjusted without

any hand tools. - Sweepable high lower structure, structure preventing water and dirt accumulation,

- Casing insulating unwanted vibrations,

- Modular structure suitable for two-way use,

- IP54 Problem-free smart servo engines,

- IP68 stainless weighing module

- IP54 light barrierv

- Belts suitable for exposed foodstuff

- Ability to enter 100 different product types

- Program controlled belt speed and direction

- Easy reporting to USB memory

- Print out from USB or Ethernet printer

- Windows Excel complaint reporting

Technical Specifications

| Model | HX300-FS | HX600-ST | HX3000-ST | HX6000-ST |

|---|---|---|---|---|

| Maximum Speed | 450 pcs/min | 250 pcs/min | 150 pcs/min | 120 pcs/min |

| Capacity | 5 – 300g | 5 – 600g | 50 – 3000g | 50 – 6000g |

| Maximum Accuracy* | ± 0.1 g | ± 0.1 g | ± 0.5 g | ± 1.0 g |

| Belt Width | 200mm | 300mm | ||

| Belt Length | 200mm | 300 – 400mm | 350 – 400 – 450mm | |

| Belt Speed | 0.4 – 3.25m/h | 0.4 – 1.5m/h | 0.2 – 1.5m/h | 0.1 – 0.8m/h |

| Protection | IP56+ | |||

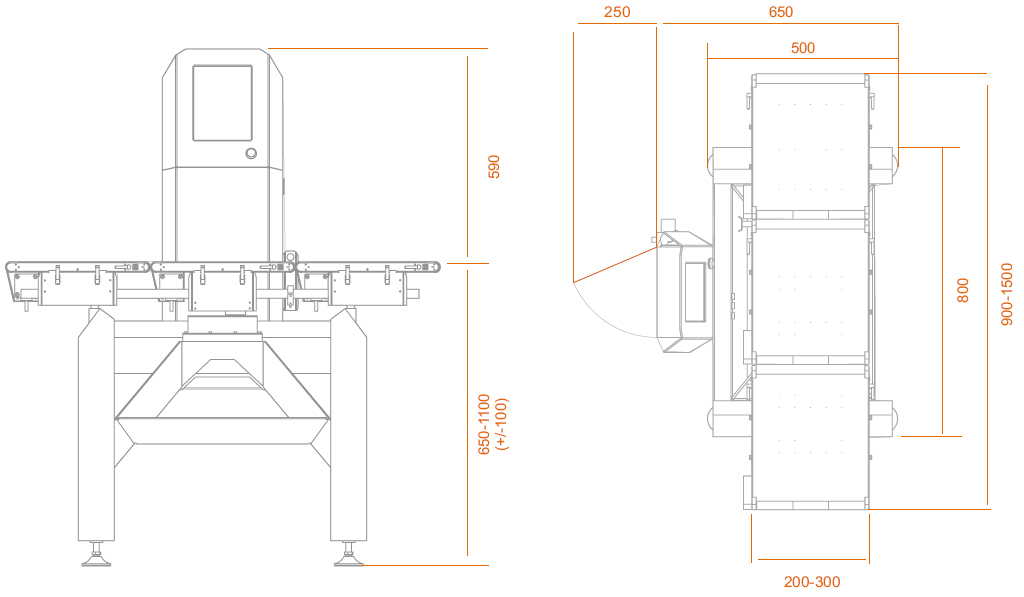

| Height from the Floor | 650–1100mm ve +/- 100mm | |||

| Conveyor | TPU Thermoplastic Belt | |||

| Engines | 24V DC Brushless Servo Motor | |||

| Feeding | 210-240V AC 50/60Hz | |||

| Power Consumption | 400W | |||

| Operating Temperature | -10°C / +50°C | |||

| Weight | 120kg | |||

| Given according to the standard conditions It may vary depending on the product type, belt speed and ambient conditions. | ||||

| Standard Equipment | Options | |

|---|---|---|

|

|

|

Dimensions