Double seam inspection SEAMetal SD

- SEAMetal SD – Double seam scope for beverage cans

- SEAMetal SD – Standard definition double seam scope for food cans

SEAMetal SD – Double seam scope for beverage cans

Description

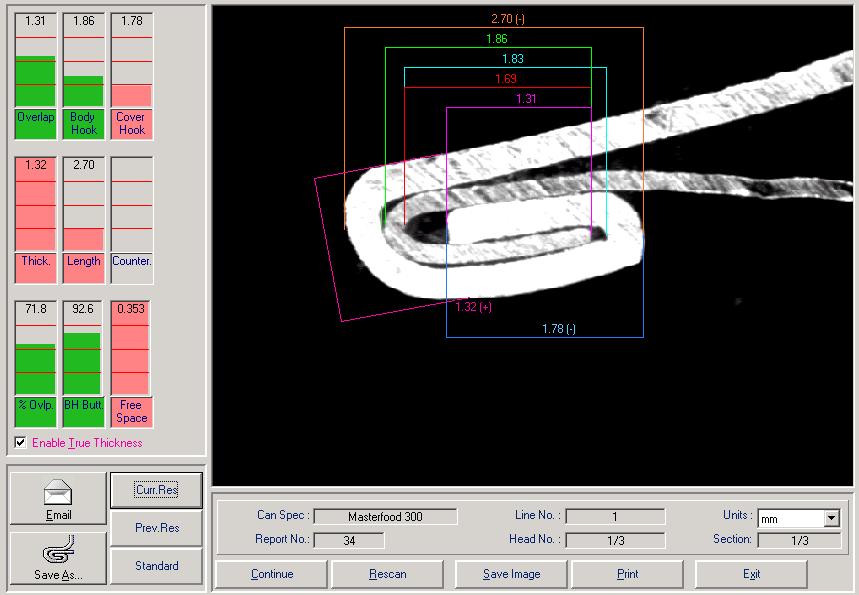

Double seam scopes have advanced dramatically during the last decade. Quality By Vision is proud to introduce the SEAMetal SD – standard definition double seam inspection system for beverage cans.

Offering the same capabilities as the industry-leading SEAMetal HD double seam evaluation and measurement system, but utilizing standard definition video, the software is able to meet todays most rigid beverage can filler requirements for double seam quality control, at a lower cost than ever before!

The price and features package make the SEAMetal SD perfect for smaller beverage plants and craft brewers.

Beverage companies are under pressure to downgauge (reduce lid diameter), reduce material thickness and increase production speed. This means that there are now more seaming problems than ever before!

This version of SEAMetal is easy to learn and the most user-friendly yet. SEAMetal SD is a low cost, high quality, repeatable and flexible solution for double seam evaluation.

SEAMetal SD is the third generation of double seam scanner by Quality By Vision. The company has never stopped improving and developing this system since 1993, when it produced the world’s first computerized fully automatic double seam scanning system: SEAMetal 9000X.

This version offers features like ExcelTM integration, zoom in, resizeable windows, new SPC system, new report system. You can now see the image better and get a much more accurate scan measurement! The software runs under WindowsTM operating systems (including Windows 7).

Key benefits

- Low cost seam scan!

- Standard definition images!

- High GR&R

- Flexible and customizable

- Flexible reporting & SPC statistics

(no need for PhD to understand!) - Great technical support!

- Fantastic picture quality

Features

- Each measurement can be measured automatically (less than 1 second per image), manually or configured to use an external caliper or gauge.

- Centering device ensures image is ideal and blocks unwanted light.

- Free SPC system, easy to use, easy to understand, great graphics, supports drilldown directly from SPC graphs!

- Tight integration with Excel for automatic, customizable reports!

- True thickness option for accurate double seam thickness analysis, without requiring external calipers or gauges!

- Adaptive detection algorithm – improves accuracy by training detection system with hard-to-detect double seams!

- Multilingual! Translations available to most languages!

- Network support – allows secure access to other SEAMetal HD systems through the network, as well as remote report viewing through local and remote network!

- Customizable reports!

- Supports rechecks – in situations where seamer adjustments were performed.

- Supports undo to avoid operator mistakes!

- Communicates with any SPC data collection system!

- Runs under Windows 2000/XP TM.

- SEAM-explorerTM allows R&D teams to inspect any radius, angle, distance or area within the double seam!

- External gauge support (e.g., can height, flange width, double seam thickness, double seam length and more!).

- Optical unit is portable, complete with portable saw!

- CE certified!

- Pre-focused, Pre-calibrated.

- Optional gauge attachments (e.g., Countersink gauge, thickness gauge).

- Competitive upgrades for seam inspection systems from other manufacturers!

Specification

| Case | Stainless steel |

| Resolution | (SD)0.0005″ (one half thousandth) or better |

| Interface | USB2 |

| Centering device | Variable (depending on can type) |

| Optical units: | Call for details |

SEAMetal SD – Standard definition double seam scope for food cans

Description

Using the same software as the acclaimed SEAMetal HD for double seam measurements, the SEAMetal SD double seam scope is the perfect tool for companies that don’t require the high resolution capabilities of the High Definition version.

The SEAMetal SD system is the latest version of our SEAMetal 9000 seam scope, the most widely used seam inspection system in the world, with over 1,000 units installed. SEAMetal 9000 was also the world’s first automatic seam inspection system, introducted in 1993.

Destructive double seam measurements are critical to ensure that the can is closed properly, meaning it will not leak or be exposed to harmful pollutants and contaminants. For this purpose sampling of cans using an optical double seam visual inspection is necessary.

SEAMetal SD is a low cost, high quality, repeatable and flexible can measurement solution to your double seam requirements. It is easy to learn and master and it holds the highest GR&R (repeatability and reproducability) ratings in the industry, in trials held by customers and independent third parties.

The latest verison of SEAMetal SD offers features like microsoft Excel integration, zoom in, automatic email alerts, network connectivity, a new SPC system and a new reporting system. You can now see the image better and get a more accurate measurement than ever before, all for a competitive price.

Key benefits

- Low cost!

- Standard definition images

- Highest GR&R in the industry

- Flexible and customizable

- Flexible reporting & SPC statistics

(no need for PhD to understand) - Great technical support!

- Fantastic picture quality

Features

- Each measurement can be measured automatically (less than 1 second per image), manually or configured to use an external caliper or gauge

- Centering device ensures image is ideal and blocks unwanted light

- Free SPC system, easy to use, easy to understand, great graphics, supports drilldown directly from SPC graphs!

- Tight integration with Excel for automatic, customizable reports

- True thickness option for accurate double seam thickness analysis, without requiring external calipers or gauges!

- Adaptive detection algorithm – improves accuracy by training detection system with hard-to-detect double seams

- Multilingual! Translations available to most languages!

- Network support – allows secure access to other SEAMetal HD systems through the network, as well as remote report viewing through local and remote network

- Customizable reports

- Supports rechecks – in situations where seamer adjustments were performed

- Supports undo to avoid operator mistakes

- Communicates with any SPC data collection system

- Runs under WindowsTM operating systems!

- SEAM-explorerTM allows R&D teams to inspect any radius, angle, distance or area within the double seam!

- External gauge support (e.g., can height, flange width, double seam thickness, double seam length and more!)

- Optical unit is portable, complete with portable saw!

- CE certified!

- Pre-focused, Pre-calibrated

- Optional gauge attachments (e.g., Countersink gauge, thickness gauge)

- Competitive upgrades for seam inspection systems from other manufacturers!

Specification

| Enclosure | Stainless steel and Anodized aluminum |

| Resolution | 0.0005″ (one half thousandth) or better |

| Interface | USB |

| Centering device | Variable (depending on can type) |

| Optical units | Call for details |