Industrial Belts For Meat, Poultry, Seafood, Confectionery, Airports, Packaging & Textile

- Seamless belts for vertical form fill sealers

- Conveyor and process belts for meat, poultry and seafood

- HACCP conveyor and process belts for conefectionery

- Conveyor and process belts for airports, materials handling and post office automation

- Post office Automation

- Curve belts

- Finishing, cutting and packaging Fabric Inspection Automatic Cutting Packing

- Nonwoven and diapers Corss-Lappers Diapers Production

- Belts for tangential drives Spinning Machines Open-End Texturing Machines

- Industrial laundries

- Spinning aprons

- Spindle tapes

- Coots for pressure rollers

- Texturing aprons

- Texturing cots

- Condenser rub aprons

Seamless belts for vertical form fill sealers

Key Features

- Total surface uniformity thanks to the seamless technology (no joint)

- High and constant surface’s coefficient of friction

- High flexibility

- Absolute thickness regularity all over belt’s length and width

- Perfect dimensional stability

- Precise fabrication: contersunks, grooves, slots, perforations

Benefits

- High production’s precision thanks to the high and constant coefficient friction

- Long service life thanks to excellent wear and tear resistance

- Suitable for high operating speed

- Time and cost saving as no lubricant is required

- Suitable for any kind of packaging

Conveyor and process belts for meat, poultry and seafood

Key Features

- Excellent resistance to cut and abrasion

- Superior resistance to most aggressive fats and oils

- No edge fray

- Very high flexibility

Benefits

- Long life even with scrapers

- Highest reliability and increased belts life

- No contamination by fibres

- Knief edge.Enery saving

HACCP conveyor and process belts for conefectionery

Key Features

- Wide range pf coefficients pf friction

- Superior resistance to abrasion and to most aggressive fats and oils

- No edge fray

- Very high flexibility

- Resistance to low temperature

Benefits

- Perfect product positioning on the belt

- Superior belt’s life expectation

- No combination by fibres

- Knief edge. Energy saving

- Long service life

Conveyor and process belts for airports, materials handling and post office automation

Features and benefits

- Low energy absorption

- Flame retardant according to EN20340-ISO 340

- Quiet running

- Absolute working safety

- Long life

- Very high resistance to abrasion and impacts

- Wide range of surface patterns to satisfy and conveying requirement

- Technical assistance from the project design

- Worldwide 24-hours prompt response for installations

Post office Automation

Features and benefits

- High capacity of conveying and constant coefficient of friction

- Anti-glazing

- Excellent resistance to abrasion and wearing

- Long life

- Dimensional stability

- Perforated belts can be supplied to Customer design

Curve belts

Features and benefits

- Absolute precision

- Excellent flatness and superb flexibility

- Suitable for small pulley diameters

- Wide range of surface patterns

- Flame retardant version also available according to EN20340-ISO 340

- Long life

Finishing, cutting and packaging Fabric Inspection Automatic Cutting Packing

Advantages of belts:

- Absolute conveying precision

- Low noise

- No damage to fabrics

- optimal friction coefficient

- Air permeable

- Long service life

Nonwoven and diapers Corss-Lappers Diapers Production

Advantages of belts:

- High conductivity

- Suitable for high speeds

- Excellent evennesss

- Lightness

- Excellent evennesss

- Excellent mechanical resistance

- High resistance oil, greases and chemicals

- Long service life

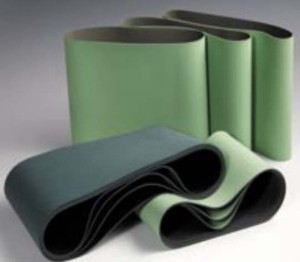

Belts for tangential drives Spinning Machines Open-End Texturing Machines

Advantages of belts for tangential drives:

- High duty and energy saving

- High transmittable stability

- Antistatic

- Low noise

- High resistance to abrasion

- Constant friction and excellent adherence

- High resistance to heat, oils and dust

- Outstanding straight running

- Long service life

Industrial laundries

Advantages of belts:

- High resistance to wear

- Total conveying uniformity

- Low noise

- Excellent drag

- No damage to textiles

- Wide variety of surface patterns

- Easy and quick installation of Fast Joint belts

- Long service life

Spinning Aprons

Advantages

- Great uniformity in spinning

- Very good resistance to wear, spinning oils and cracking caused by ozone

Spindle tapes

- Energy saving

- Antistatic

- Excellent flexibility

- High chemical-physical-mechanical resistance

- Low noose

- Uniformity of yarn count

- No dust accumulation on edges

- Long service life

Coots for pressure rollers

Advantages:

- Total absence of winding

- High conductive surface, which can be ground to a minor-finish

- Excellent fiber control, thanks to elasticity and permanent friction

- Perfect seal thanks to various types of available reinforcement and direct vulcanization

Texturizing cots

Advantages

- High coefficient of friction

- Resistance of spinning oil

- Very good-resisyance with heat, even after a long running period

- Good antistaticity

- High resistance to aging and cracking

Condenser rub aprons

Advantages

- Excellent rubbing

- High carcass resistance

- Very good resistance to spinning oils

- Long life: they work on any type of condenser and any type of fibre