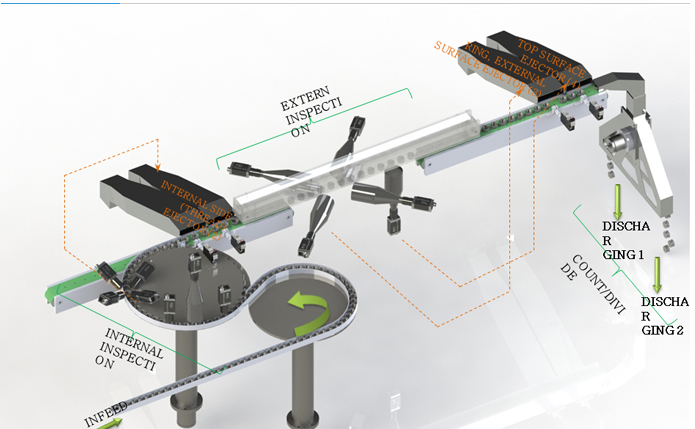

PS-21 EC 2000 S4

PS-21 EC S4 2000 bottle closures inner/outer surface Precision Automatic Inspection machine

PS-21 EC 2000 S4 is automatic inspection machine that is build in linear type structure and inspect bottle closure inner/outer whole surface. By using angles of lots of cameras , inspect the fine details under the screw thread of cap inner wall. This model combines elements of inspection and measurement equipment.

Feature

- Cap In/External whole Inspection

- Deliver on Vacuum Conveyor

- Various Materials (AL/ST/Plastic) Inspection

- Various Color Inspection

- High-resolution Digital Camera and megapixel Lens

- Long Life High-brightness LED

- Discharging Products Counting

Inspection ITem

- Mold number

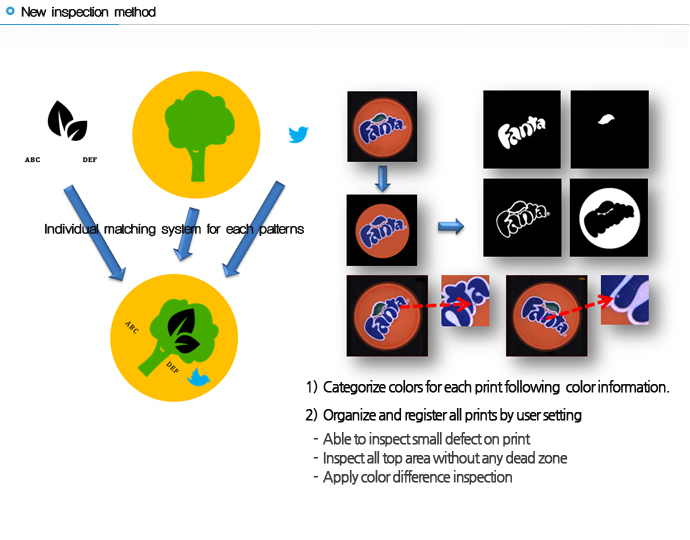

- Top round, contamination, printing

- nternal(side)/External surface

- PLUG contamination, foreign material, deformation

- Entire inner surface contamination, foreign material, scratch

- Outer surface contamination, foreign material, scratch

Standard Specification

| Size | 1,400 X 2,500 X 2,200(H) |

| Weight | 900kg |

| Speed | 2,500CPM |

| Electric Specification | 220/380/440V, 3Ph, 50/60Hz |

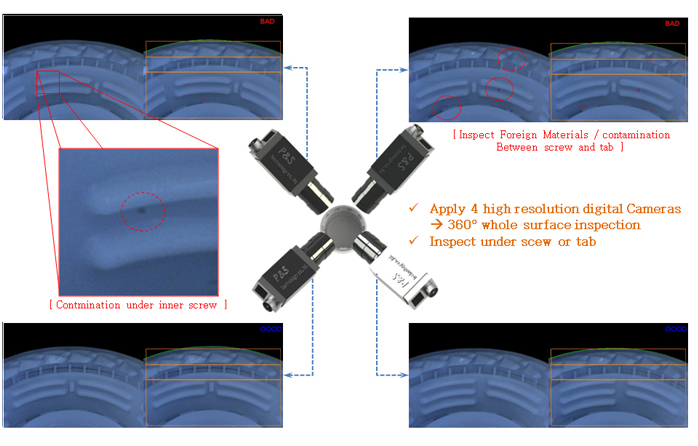

New Inspection Method

Sample Flow

Fare inspection round contamination / foreign material/ stratches

Upper internal side inspection contamination / foreign matter/ stratches

Lower inter side inspection contamination / foreign matter/ stratches

PLug inspection contamination / foreign matter/ stratches

Inner surface inspection contamination / foreign mattrer/ stratches

Top surface inspection OVALity contamination / foreign matter/ Print

External surface inspection 2 contamination / foreign matter/ pollution/stratches

External surface inspection 1 contamination / foreign matter/ pollution/stratches

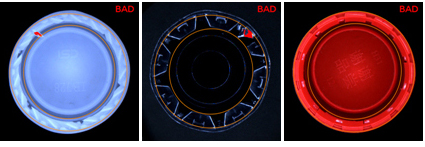

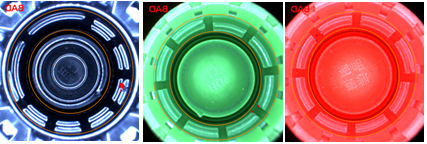

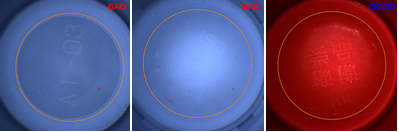

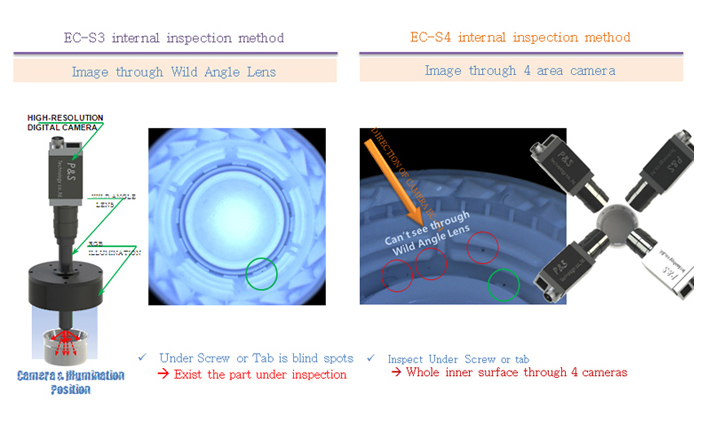

Compare Internal Inpection method EC-S3, ec-S4

Internal Side Inpection

PS-21 EC S2 2000

PS-21 EC S2 2000 Bottle closure inner/outer surface Inspection machine

PS-21 EC S2 2000 is the inspection machine to inspect inside and outside of cap closure. Aluminum / Plastic / Steel cap closure can be applied in and from 22mm to 43mm able to be inspected. Cap closures are safely moved and detected by vacuum conveyor.

It is linear type structure. We applied special lens to perfectly find dirties on inside and outside. Bad products which detected by the system are ejected at the conveyor.

The final stage of inspection, It counts quantity and automatically divides cap closures according to setting value into the boxes.

Feature

- Include control rack inside of machine

- Linear type structure

- Apply special lens and illumination

- Quick & Easy Installation

- High speed eject system

- Provide customized inspection items

- Available for 1pcs/2pcs cap

- Stable transfer on vacuum conveyor

- Include cap interval device

Inspectione ITem

- Inspect Inner seal

- Inspect contamination of outer surface

Standard Specification

| Size | 600 X 1,800 X 1,900(H) |

| Weight | 700kgKg |

| Speed | 2,500CPM |

| Electric Specification | 220/380/440V, 3Ph, 50/60Hz |

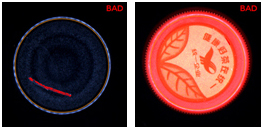

Aluminum Closure Inspection System

Aluminum ClosureInside Inspection

Aluminum ClosurePrint Condition Inspection

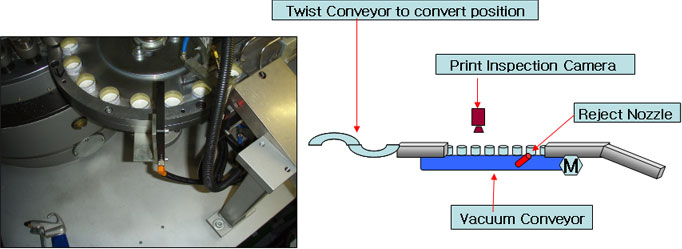

- The cap will been conversion to look Top seal surface after using twist conveyor.

- After been conversion, the camera will detect cap print condition as center off and some duty printed cap.

- During the travel under the camera, the strong vacuum conveyor will convey the cap to stable inspect.

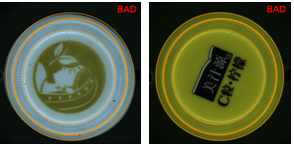

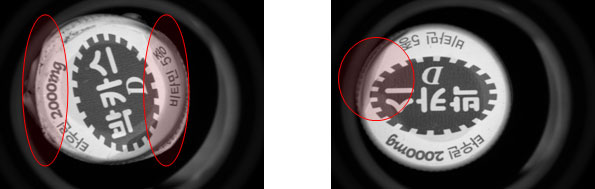

Aluminum Closure Print Condition Inspection

|

|

| Damaged on Top | Damaged on Top Left |

|

|

| Print Spread | Print Spread |

|

|

| Tear on the top | Cut on the top |

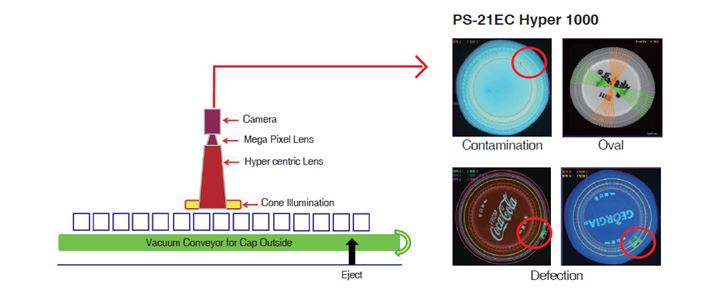

PS-21 EC Hyper 1000

PS-21 EC Hyper 1000 Bottle closure outer surface Automatic Inspection machine

PS-21 EC Hyper 1000 is automatic inspection machine that is build in linear type structure and inspect bottle closure outer surface. This model can be applied for aluminum, plastic, and steel material closures, and it guarantees the stable product transfer with vacuum conveyor, qualified inspection technic, and ejecting system.

This model include the special P&S own design “Special” lens, with this lens machine inspects the whole outer surface of cap through one color camera.

The EC is acceptable to feed the cap in the following diameter from minimum 22mm to maximum 43mm. Specially, as the Hyper-centric is installed on the upper side of conveyor, this structure can prevent the miss ejecting which can be occurred from interference through contaminant on the lens when the lens under conveyor.

Feature

- Include control rack inside of machine

- Linear type structure

- Apply special lens and illumination

- Quick & Easy Installation

- High speed eject system

- Provide customized inspection items

- Stable transfer on vacuum conveyor

- Include cap interval device

Inspection Item

- Inspect contamination of outer surface

Standard Specification

| Size | 675 x 980 x 1,900mm (H) |

| Weight | 300kg |

| Speed | 1,500CPM |

| Electric Specification | 220/380/440V, 3Ph, 50/60Hz |

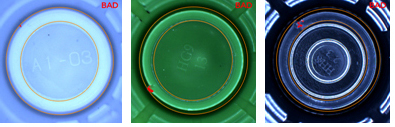

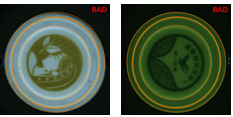

Inspection Anlge of patent % special Lens

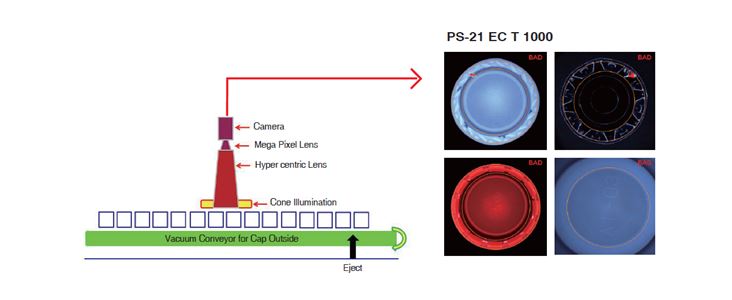

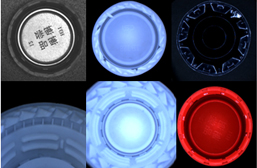

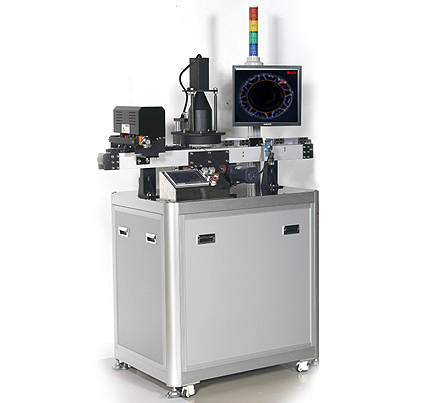

PS-21EC T 1000

PS-21EC T 1000 Cap Closure Internal Inspection Machine

PS-21EC T 1000 is the latest stand alone type inspection machine. It is specialized for internal inspection of cap closures.

The motive of this machine can be described with one sentence followed “Guarantying product quality to minimize the end user’s complains at the filling lines. “

By providing this machine to the end user, the cap manufactures can be free with the any financial loss or complains from their customers.

Feature

- Reduce down time

- Improves product quality

- Improves line efficiency

- Monitoring production

- Minimizes fault ejection

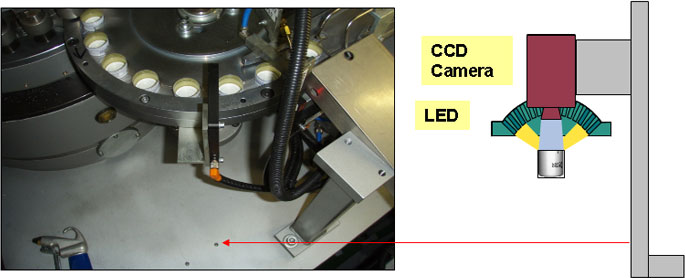

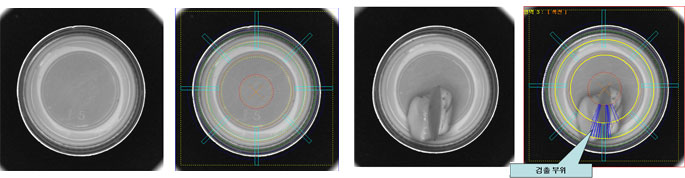

- High resolution digital CCD color and Mono camera apply strobe type? LED illumination

- Telecentric lens apply for internal inspection

- Stable transfer on vacuum conveyor

- patent cone type mirror application for plastic cap internal inspection

Inspection Item

- Internal inspection

Standard Specification

| Size | 675 x 980 x 1,900mm (H) |

| Weight | 300 Kg |

| Speed | 1,500CPM |

| Machine Power | 220/380/460v, 3ph, 50/60hz |

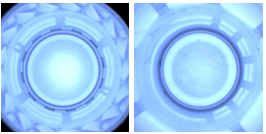

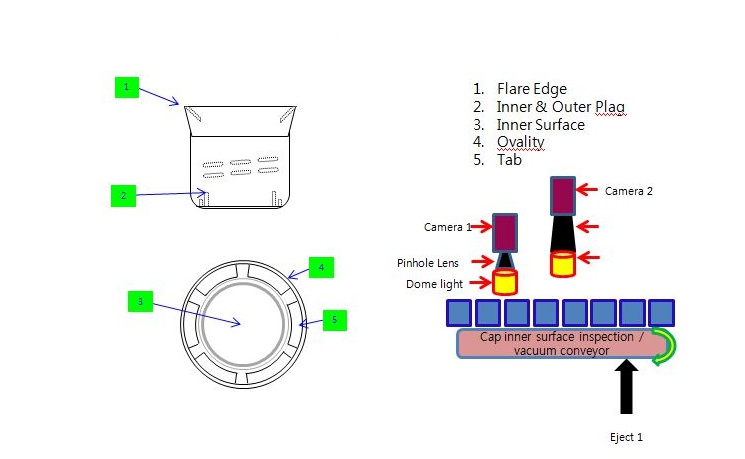

Position both Camera $ illumination

Machine Configuration