Online Density Meter

ANALYTICAL FLOW TECHNOLOGIES LLC

manufacturer of the American-made DENSITRAK® DENSITY METER, provides a variety of Liquid Density Meters to suit highly specific applications in the:

- Petroleum Pipeline and Refinery

- Chemical and Petro-Chemical

- Semi-Conductor Production

- Pharmaceutical industry

- Water Treatment/Wastewater

- Fluid Product Blending

- Pulp/Paper Manufacturing

- Slurries

- Various other industries

The DENSITRAK® DENSITY METER, originally developed by Calibron Systems, Inc and marketed by Honeywell Enraf Americas since 1994, the DENSITRAK® DENSITY METER is now sold and serviced by former Honeywell Engineer and founder of ANALYTICAL FLOW TECHNOLOGIES LLC, Paul Heinritz

The DENSITRAK® DENSITY METER is available in both a “U” Tube and Straight-Through design, utilizes the spring mass principal for measuring liquid density.

NEW ELECTRONICS AND MICROPROCESSOR UPGRADE; DENSI-Trax SOFTWARE PROGRAM.

State of the Art Electronics and a Windows® based software tool for communicating and configuring the Density Processor.

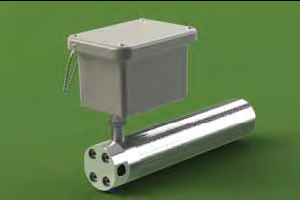

DENSITRAK® D625 Liquid Density Meter

FEATURES

- Compact

- Lightweight (<15LB)

- High Resolution

- Material is suitable for most corrosive applications

- Built in RTD & 4-20mA temperature transmitter

- High benefit-to-cost ratio

- Frequency output for density calculation with customer-owned flow computer

- Available with a density processor and a linearized 4-20mA output

- One year warranty parts and labor

- Made in the U.S.A.

APPLICATIONS

- Interface Detection

- Live Density Monitoring

- Product blending

- Process quality control

- …and many more

INDUSTRIES

- Petroleum Pipeline & Refinery

- Chemical & Petro-Chemical

- Pharmaceutical

- Water Treatment/Wastewater

- Semiconductor Production

- Pulp/Paper Manufacturing

- …and many more

SIGNAL PROCESSING UNIT FOR DENSITY (S.P.U.D. 800) DENSI-Trax SOFTWARE

DENSI-Trax software is a tool for use with the DENSITRAK® LIQUID DENSITY METER and provides the following functions:

- Configure the input and output (I/O) settings

- Modify the 4-20 mA span for density

- Configure the two independent N/O or N/C Alarm contacts

- Configure the calibration coefficients inside the processor

- Monitor/record live data for density, temperature, etc

- Use as a data logger to record Meter data to a “comma separated value” text file

- A superior feature of this software is its ability to show historic data and trends. Data can be transferred directly into reports, spreadsheets or analysis programs. Data can be examined and archived on any Windows® compatible machine and can be printed out in various formats as required.

- This instrument has two independent scalable outputs so it can measure live fluid density and temperature simultaneously.

- Communication options include USB, RS232, and RS485 (2- WIRE) protocols.

DENSITRAK® D625 PRODUCT SPECIFICATIONS

| Density Operating Ranges 0.40 – 2.00 grams/cubic centimeter [gr/cm3] |

Maximum Density Span 0.70 gr/cm3 (range can be extended with reduction in accuracy) |

| Density Resolution 0.00001 gm/cm3 |

Meter Accuracy 0.0001 gr/cm3 |

| Repeatability Better than 0.01% |

|

| Operating Temperature Standard: 32°F to 212° F (0°C to 100°C) Optional: -58°F to 302°F (-50 to 150°C) |

MAX Temp. Differential ΔTmax = 90°F [50°C] |

| Operating Pressure Range: 0 to 2,220 PSI [0 – 149 bar] ANSI 900 Lbs. RATING Hydrostatic Test: 3330 PSI |

Flow Rate MIN: .25 Gallons per Minute (GPM) MAX: 20 GPM 2 GPM Recommended |

| Frequency Signal Output Nominal 0.30 kHz to 3.0 kHz |

Temperature Sensor 3 Wire 100Ω Pt RTD |

| Power Requirements VOLTAGE: 24 VD CURRENT: 50 to 150 mA nom. |

Materials of Construction Standard Wetted Parts: 316/316L Stainless Steel, HASTELLOY® C276 Non-Wetted Parts: 304 Stainless Steel |

| Electrical Classification Designed to meet NEC/CSA Class 1, Div. 1, Group C & D, CE Mark Housing Approved: CSA, FM, EExd, UL RoHS Compliant |

Physical Dimensions SEE APPENDIX DRAWING Shipping Weight: Approx. 16 pounds |

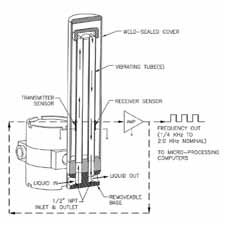

PRINCIPLE OF OPERATION

The DENSITRAK® D625 Liquid Density Meter utilizes the oscillating U-tube as a technique to establish the density of liquids and gases based on an electronic measurement of the frequency of oscillation, from which the density value is calculated. A change in the vibrating mass, (as a result of change in the fluid density) shifts the resonant frequency. The meter produces a square wave frequency output signal that can be processed by a microprocessor based signal converter (SPUD) or commercially available flow computer (Omni Flow Computer for example). The microprocessor utilizes built in algorithms to compute density based on fluid composition, temperature, and pressure. Each densitometer has a unique set of Calibration Coefficients which are used by the micro-processor in calculating the live fluid density.

These coefficients are determined by careful calibration in the Analytical Flow Technologies laboratory for each meter individually.

We offer a variety of DENSITRAK® meter models and our engineers review each Sales

Application to determine the DENSITRAK® D625 model that best suits your specific

application.

D625-A0-00-00

Applications

- Petroleum Pipeline & Refinery Industries

- Chemical & Petro-Chemical

- Hazardous/Explosive Environments

D625-A0-00-02

D625-A0-00-03

Applications

- Chemical Processing

- Waste-Water Management

- Petroleum Pipeline & Refinery Industries

- Chemical & Petro-Chemical

- Hazardous/Explosive Environments

**D625-A0-00-03 includes LCD Display

D625-A0-00-01

D625-A0-00-04

Applications

- Semiconductor Production

- Pharmaceutical

- Chemical Processing

- Waste-Water Management

- Non-Hazardous Installations

**D625-A0-00-04 incudes LCD Display

SVT

Applications

- Water & Wastewater Treatment

- Fluid Product Blending & Interface Detection

- Pulp & Paper Manufacturing

- Chemical Processing

- Power Generation

- and many more